Try our free online tool to find your connectors

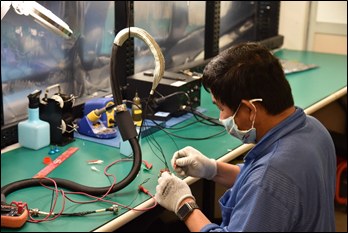

WORKMANSHIP

All B&A Bob cables are manufactured by certified technicians and comply with specifications and requirements described within the standards below:

Standard | Title |

JPL D-53900 | JPL Harness Manufacturing Requirements and Process Specification |

NASA-STD-8739.4A | NASA Standard for Crimping, Interconnecting Cables, Harnesses, and Wiring. |

MATING COMPATABILITY

Our standard Bob Cables are designed to mate with connectors of B&A standard Break out Box (BOB) 180023.The cables can be manufactured to mate with other type of BOBs displayed below.

(For details visit our BOB product page)

| B&A BOB 180075 | B&A BOB 180074 | B&A BOB 180023 (Standard) |

|

|

|

|

Number of Contacts | 128 | 61 | 61 |

Connector Part No. RED (right) | D38999/20FJ35SN | MS27656T25F61SN | MS3470L24-61S |

Connector Part No. BLACK (left) | D38999/20FJ35PN | MS27656T25F61PN | MS3470L24-61S |

Banana Plug Type | Regular | Regular | Miniature |

Finish | Anodized | Anodized | Powder coated |

Wiring | 20 AWG Shielded | 20 AWG Shielded | 22 AWG Regular |

AVAILABLE CABLE DRAWINGS

Over 250 available drawings for various connector choices to choose. Our cable drawings are available for the connector types presented below:

Circular

D-Sub

D-Sub Micro-D

Special

CUSTOMIZATION

Cables can be assembled based on customer preferences and requirements.

- Standard length of our Bob cables is 6 ft.

- Standard external sleeving color is Black.

- Black and Yellow sleeving shown below, other colors are available.

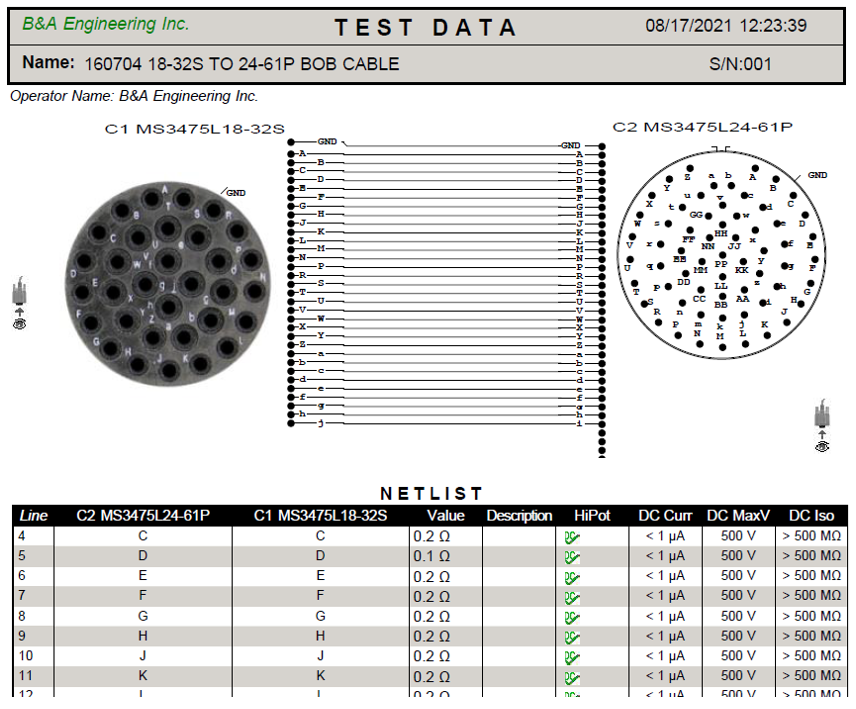

TESTING

All Bob cables are tested in accordance with requirements described in section 18 of NASA-STD 8739.4A unless specified by customer. A Test Data Report is provided with each Bob cable.

The cables are tested to satisfy the following requirements:

- Continuity with resistance measurement between contacts

- Dielectric Withstanding voltage (DWV) or Hi-Pot

- Insulation Resistance (IR)

Optional stray voltage measurement is available upon request. (Not required by NASA-STD 8739.4A)

DOCUMENTATION

The following documentation can be provided upon request:

| Test Data Report | Contains requirements, measurements, and Pass/Fail status. Printed copy is delivered with all Bob cables. An electronic version can be requested any time after delivery of product. |

| Traveler | A record of manufacturing operations with limited details. Some quality inspection photographs included. Not delivered with product. Can be requested if required. |

| IBAT | Optional IBAT (Instructions for Built, Assembly and Test) document may be requested. Contains complete record of manufacturing operations, quality inspection points, material traceability, inspection Photographs, etc. Satisfies most quality team requirements. |

| Feature | Traveler | IBAT |

| Product Information |  |  |

| Material Kit Verification |  |  |

| Crimp Pull Test Results |  |  |

| Contact Retention Push Test Results |  |  |

| Back Shell Torque Measurements |  |  |

| Cable Labeling Verification |  |  |

| Cable Testing Status |  |  |

| Inspection Photos of Connector Faces |  |  |

| Photos of Final Product Prior to Delivery |  |  |

| Inspection Photos of Connector Close Out |  | |

| Inspection Photo of Connector and Backshell Part Number |  | |

| Inspection Photos of Crimp Pull Test Specimens Prior and after Testing |  | |

| Inspection Photos of Random Contact Crimps Prior To Population |  | |

| Inspection Photos of Connector Potting Operation (If applicable) |  | |

| Complete List of Equipment including Calibration Data |  | |

| Traceability of Material |  | |

| Operation Details and Contract Information |  |

EASY ORDER

- Available free online tool to choose required connector and request quote.

- Cable drawing can be produced if connector is not found in database.

- Express delivery available.

Try our free online tool below: